Ultrasonic Polishing Machine with micro vibration stroke and extra-high frequency (22,000 times per second), which can easily handle most intricate jobs for various molds and dies.

The difficult traditional process of slots, ribs, detail corners, intricate areas becomes so easy with time saving, and efficiently reach a quality result of polishing and finishing process.

The ultrasonic cutting machine vibrate approximately 40,000 times per second (40 kHz). Thanks to this movement, the ultrasonic cutter can easily cut rubber, resin, non-woven fabrics and composite materials. The basic principle is to convert electrical energy into mechanical vibrations for clean, efficient material cutting.

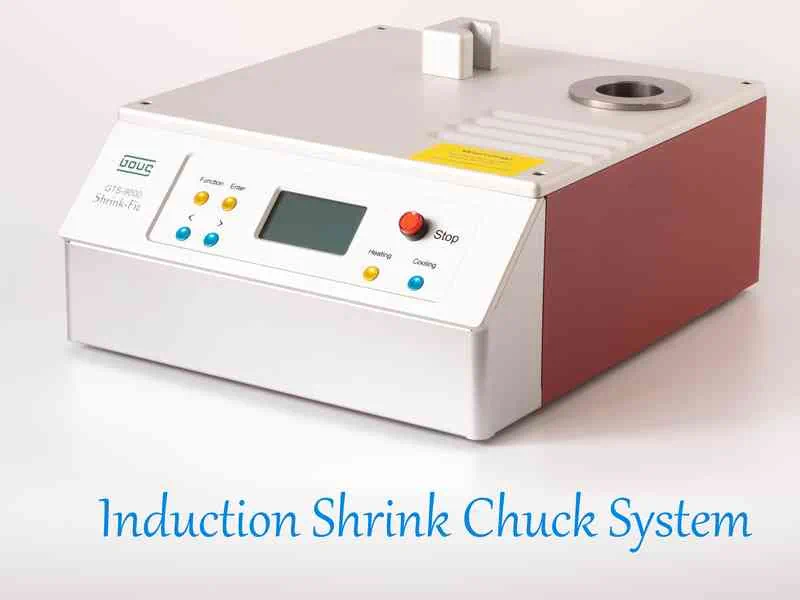

Induction shrink fit machine utilizes the principle of thermal expansion and contraction to secure cutting tools. The holder is heated via induction or other methods, causing it to expand. This allows for the insertion of a tool with a slightly smaller diameter, ensuring a tight fit upon cooling. Shrink fit tool holders provide superior rigidity and vibration damping compared to traditional clamping methods, enhancing machining accuracy and tool life. They are commonly used in high-precision machining operations involving highspeed cutting and heavy loads.